- Home

- Pultrusion Products

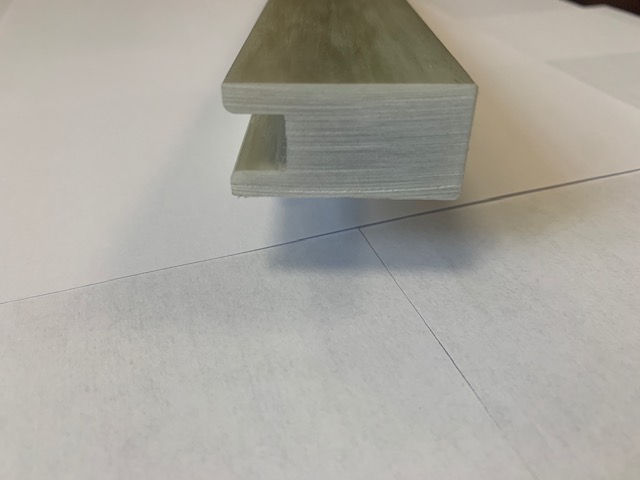

- Custom Pultrusions

For over 40 years Liberty Pultrusions has been a premier leader in the pultrusion industry. Our engineers, quality assurance team and customer service team can provide assistance with the custom design of your product and see it through the entire manufacturing process. If we do not have the standard structural profile you need, we can create custom FRP profiles.

We customize pultrusions to meet your specific requirements, in regard to resin matrix, composite reinforcement, shape, and design. If you are not sure what you need, our engineering staff can assist you. Contact us to get started or for a price quote.

BENEFITS OF CUSTOM PULTRUSIONS

Because we design and manufacture custom pultrusions ourselves, we offer very competitive pricing and a high quality, lasting product. Compare pultruded material with other types of material.

Benefits of pultruded products include:

- High strength-to-weight ratios

- Corrosion resistance

- Heat resistance

- Dielectric properties

- Dimensional stability

- Weatherability

Benefits of custom pultrusions include:

- A specific design to meet your unique application needs

- Assistance from experienced engineers

- Optimized profiles for strength, durability & reliability

- Lower life-cycle cost

APPLICATIONS USED FOR CUSTOM PULTRUSIONS

Liberty Pultrusions has manufactured custom pultrusions across many types of industries for the below applications:

- Fiberglass Struts

- Pipe Supports

- Electrical Supports

- Cable Tray

- Static Arrestors

- Busbar Insulators

- Cored Tubing / Handles

- High Jump Poles

- Specialty Consumer Products

- Tree/Vine Supports

- Radomes

- Residential Door Profiles

- Residential Window Profiles

- Commercial Door Profiles

- Commercial Doorframe Profiles

- Window Reinforcements

- Utility Line Markers

- Hog Pen Supports

- Demisting Blades

- Umbrella Poles

- Roll-Up Door Panels

- Telescoping Ham Radio Poles

- Wind Blades

- Armour Plate

- Refrigeration Components

- Highway Sound Barriers

PROFILE DESIGN

Liberty Pultrusions’ engineering staff can assist in the design of virtually any continuous cross-sectional pultrusion profile. We can take your idea from concept to final product reality.

RESIN SYSTEMS

We can design the resin system to meet a variety of customer requirements. Some specific customer requirements may include, elevated temperatures, corrosive environments, UL rated non-conductive systems, high flexural modulus, stiffness and, of course, low cost.

Our current resin systems include polyester, vinyl ester and a variety of urethane products.

Read more about the pultrusion process for more information about how we manufacture custom pultrusions.

FIBERGLASS REINFORCEMENTS

Our engineers have a wide range of fiberglass reinforcements available to solve demanding customer requirements. We offer single end and premium multi-end rovings, continuous filament mats, stitched mats, woven roving, and other specialty glass reinforcements.

LIBERTY PULTRUSIONS FACILITY

Liberty Pultrusions can manufacture a variety of custom and standard pultrusions. We have the ability to custom design very large or small pultruded parts. We can also produce complex geometric shapes in addition to thin or thick cross-sections.

Our pultrusion manufacturing facility has been producing custom pultrusions in Pittsburgh, PA since the Westinghouse Corporation first began production in 1964.

We are committed to servicing our customers’ needs by providing superior customer support, aggressive pricing, fast delivery, and the highest quality pultrusion products available.